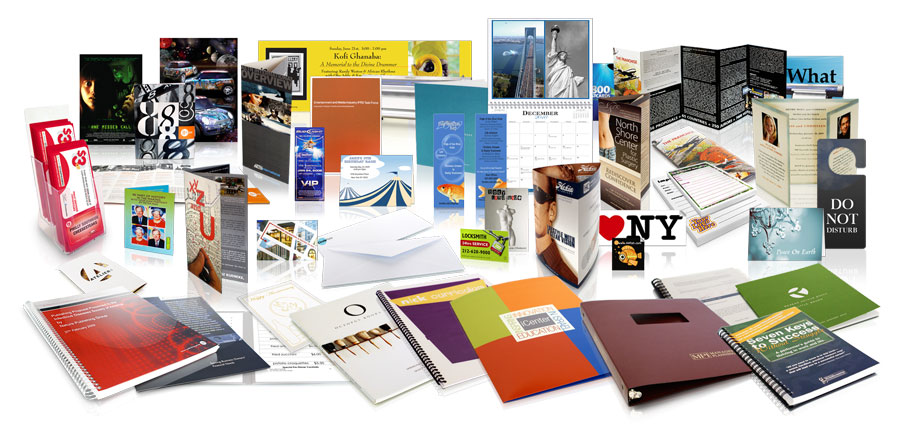

Recognizing Just How Printing Services Work to Deliver Remarkable Top Quality for Your Publications and Catalogs

An extensive understanding of printing solutions is critical for attaining remarkable high quality in magazines and publications. The trip starts with pre-press prep work, where vital choices relating to format and shade improvement are made. Selecting the suitable printing technique-- whether digital or countered-- functions as a structure for conference details task demands. The choice of top notch materials and the implementation of rigorous proofing procedures play crucial functions in the last result. Yet, the subtleties of completing touches typically identify the overall influence of your printed materials, raising the inquiry of exactly how to navigate these intricacies successfully.

The Printing Process Explained

The printing process is a complex procedure that changes electronic designs into tangible items. It normally begins with pre-press preparation, where documents are formatted and enhanced for printing. This stage includes shade correction, design changes, and proofing to guarantee that the end product satisfies top quality expectations. When the documents prepare, the next step includes picking the appropriate printing technique, such as electronic, countered, or flexography, each with its own advantages depending on the task's needs.

Following the selection of the printing strategy, the production phase commences. For offset printing, plates are created to transfer ink onto paper, while digital printing uses electronic files to print directly onto substratums. Print Shop. Throughout this phase, thorough focus is paid to color accuracy and image resolution to maintain the integrity of the original design

Post-press procedures such as reducing, binding, and ending up are important for the final presentation of published products. These procedures make sure that publications, directories, and various other published items are not just visually appealing but additionally practical and durable. The entire printing operation, from pre-press to post-press, requires competent experts to deliver remarkable quality and fulfill client expectations efficiently.

Choosing Quality Products

Selecting quality products is a vital facet of the printing process that directly influences the final item's durability, appearance, and total impact. The choice of paper, ink, and binding products plays a substantial duty in determining how your publication or brochure is viewed by its target market.

A larger paper not just feels a lot more considerable however also boosts the visual high quality of printed pictures. Furthermore, selecting acid-free paper can avoid yellowing and deterioration over time, ensuring your job stands the test of time.

The choice of ink is just as crucial. High-quality inks supply vivid colors and sharp information, which are crucial for making photographs and illustrations stand apart. Environmentally pleasant inks can appeal to eco-conscious customers, adding worth to your product.

Lastly, the binding products should be resilient yet adaptable, enabling for simplicity of usage. Alternatives like excellent binding or hardcover can dramatically affect the longevity and visual of the finished product. Ultimately, selecting top quality products will certainly improve the overall presentation and effectiveness of your published products.

Printing Techniques and Technologies

While various printing techniques and technologies have advanced for many years, each approach offers distinct purposes and provides one-of-a-kind advantages that can considerably impact the top quality and cost-effectiveness of published products. Among the most common strategies are electronic printing, offset printing, and gravure printing.

Digital printing is known for its flexibility and rate, making it excellent for brief runs and on-demand printing. Alternatively, offset printing, which makes use of a plate to move ink onto paper, is preferred for big volume runs due to its expense performance and top notch result.

Gravure printing, usually made use of for long-run publications, entails inscribing pictures onto a cyndrical tube. This method offers phenomenal picture quality and is commonly employed for magazines and packaging. Each of these modern technologies has certain applications, and understanding their staminas is important for picking the right printing solution, ensuring that the final product fulfills both financial and visual requirements.

Proofing and High Quality Control

Efficient proofing and quality assurance are indispensable parts in the printing procedure, making sure that the last product aligns with the intended design and fulfills client expectations. This phase starts with the creation of proofs-- preliminary variations of the printed product-- which can be either physical or digital. These proofs permit clients to evaluate formats, colors, and general design before mass production begins.

When the first proofs are approved, the emphasis shifts to top quality control. This involves thorough checks at different phases of the printing process. Printing experts evaluate shade accuracy, image resolution, and consistency across batches. Any type of disparities are attended to without delay to alleviate potential issues in the final outcome. Print Shop.

Eventually, effective proofing and extensive quality assurance not just enhance customer satisfaction yet likewise investigate this site decrease waste, time, and prices connected with reprints. By prioritizing these elements, printing services can supply publications and catalogs that truly reflect the vision and assumptions of their customers.

Final Touches for Presentation

The last touches for discussion are vital in raising the overall effect of published materials, guaranteeing they not just share info however additionally captivate the target market. This phase incorporates numerous elements that enhance both aesthetics and functionality, adding to a refined product.

One considerable element is the option of binding, which can dramatically affect the use and visual allure of publications and magazines. Options such as excellent binding, saddle stitching, or spiral binding should line up with the planned usage and target market preferences. In addition, the option of covers-- be it soft or difficult-- includes an additional layer of class.

In addition, ending up methods such as lamination, spot, or embossing UV layer can give structure and aesthetic interest, making the printed products extra engaging. These features not just secure the item however also create a remarkable responsive experience for visitors.

Verdict

In recap, the printing procedure incorporates numerous critical points that jointly add to the production of high-quality publications and magazines. From thorough pre-press prep work to the choice of suitable printing methods and products, each component plays a vital role in the final result. Rigorous proofing and quality assurance procedures guarantee consistency throughout the process, while thoughtful complements enhance the general discussion. An extensive understanding of these parts is important for achieving outstanding lead to published products.

A comprehensive understanding of printing services is important for attaining outstanding quality in magazines and publications. For offset printing, plates are produced to transfer ink onto paper, while digital printing you could try this out utilizes digital files to print directly onto substratums. The whole printing operation, from pre-press to post-press, requires experienced specialists to provide remarkable top quality and fulfill client expectations effectively.

Digital printing is recognized for its adaptability and rate, making it optimal for brief runs and on-demand printing.Reliable proofing and quality control are essential elements in the printing procedure, guaranteeing that the final item aligns with the intended layout and fulfills client expectations.